A research team from the Korea Institute of Materials Science (KIMS) has announced a significant advancement in cooling technology with the development of Korea’s first full-cycle magnetic cooling system. Led by Dr. Jong-Woo Kim from the Nano Materials Research Division and Dr. Da-Seul Shin from the Materials Processing Research Division, this innovative technology aims to replace conventional gas-based refrigerants and address pressing environmental concerns.

The newly developed magnetic cooling technology operates without gas refrigerants, utilizing the magnetocaloric effect to achieve cooling in solid materials. When an external magnetic field is applied, the temperature of the refrigerant material changes, allowing for efficient cooling. This breakthrough is particularly timely, as global regulations are tightening around the use of traditional refrigerants such as HFCs and HCFCs, with a complete ban set for 2030 under the Kigali Amendment to the Montreal Protocol.

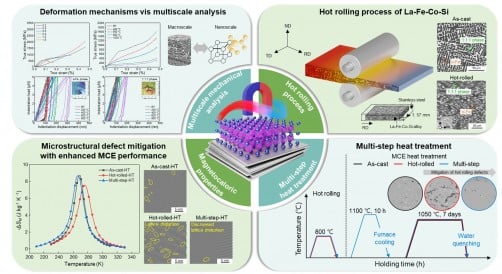

Despite its potential, the commercialization of magnetic cooling technology has faced obstacles. High production costs associated with magnetocaloric materials, particularly those reliant on rare-earth elements, have hindered price competitiveness. The research team has responded to these challenges by synthesizing various magnetocaloric materials, including lanthanum (La)-based and manganese (Mn)-based alloys. They successfully fabricated thin sheets and fine wires using advanced manufacturing processes like hot rolling, cold drawing, and micro-channel machining.

Breakthroughs in Material Production

One notable achievement from the team includes the production of large-area La-based thin sheets that are 0.5 mm thick. Additionally, they developed Gd-based fine wires with a diameter of 1.0 mm, showcasing exceptional performance at the component level. Furthermore, the team has improved the cooling performance of non-rare-earth Mn-based materials by adjusting thermal hysteresis and magnetic anisotropy.

KIMS has also introduced Korea’s first measurement system capable of directly monitoring adiabatic temperature changes in magnetic cooling materials. This advancement allows for quantitative verification of property differences based on manufacturing processes, facilitating the creation of optimized materials and components for magnetic cooling applications.

As countries worldwide shift towards environmentally friendly technologies, magnetic cooling is gaining traction as a viable alternative. In technologically advanced nations like Germany, studies have indicated that magnetic cooling systems can achieve coefficients of performance (COP) exceeding those of traditional refrigeration methods.

This trend highlights the importance of developing eco-friendly cooling solutions in line with global decarbonization efforts. The KIMS research team is committed to enhancing its technological capabilities in magnetic cooling through impactful publications and essential patents. They have already registered a domestic patent related to their magnetic cooling evaluation system and filed a corresponding application in the United States.

Looking Ahead

Dr. Jong-Woo Kim emphasized the transformative potential of this technology, stating, “Once commercialized, this technology will overcome the limitations of conventional gas-based cooling systems and provide an eco-friendly and stable cooling solution.” Dr. Da-Seul Shin further expressed the team’s goal to advance magnetocaloric technology and establish a robust domestic industrial infrastructure while also expanding into the global market.

Funding for this research was provided by the Basic Research Program of KIMS and the Creative Convergence Research Program of the National Research Council of Science and Technology (NST). The findings were published in the esteemed academic journal Rare Metals in May 2025, with Ph.D. candidate Sun-Young Yang as the first author, marking a significant milestone in the field of materials science.

The ongoing efforts by KIMS to innovate in magnetic cooling technology reflect a critical step towards sustainable refrigeration solutions that align with environmental regulations and consumer demands for eco-friendly alternatives.