Organizations are increasingly turning to technology to enhance the resilience of their supply chains, as outlined in a recent interview with Sev Kelian, Chief Information Security Officer (CISO) and Vice President of Security at Tecsys. Kelian emphasized the importance of adopting a unified strategy that integrates both cyber and physical risks, ensuring that supply chains are not only efficient but also robust against disruptions.

A common misconception when developing a supply chain strategy is treating it merely as a logistics issue. Kelian argues that it is essential to view supply chain management as a holistic framework that encompasses various elements, including procurement, planning, and risk management. Companies often underestimate the significance of digital tools, which are crucial for achieving visibility, predictive analytics, and automation in supply chain operations. These technologies are not optional; they are foundational to creating a resilient supply chain.

Kelian notes that strategy must be dynamic, evolving in response to changing market conditions and emerging threats. Prioritizing efficiency over resilience is a false trade-off. Lean operations without built-in redundancy can leave businesses vulnerable to unexpected disruptions. This principle applies to cybersecurity as well, where a resilient approach necessitates layered defenses, adaptable response plans, and continuous monitoring.

Integrating Cyber and Physical Resilience

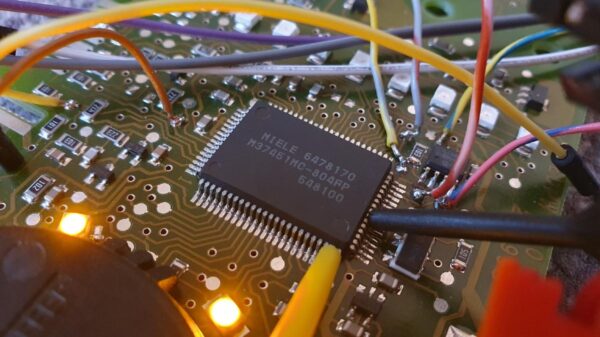

Physical and digital resilience are interconnected, and organizations that successfully integrate both will be better positioned to navigate uncertainties. Resilience involves treating cyber and physical risks as a single, integrated challenge. This approach requires embedding security at every stage of the supply chain, from vendor onboarding to logistics execution. Advanced visibility tools and zero trust principles should be utilized to enhance security measures.

Kelian stresses that a comprehensive strategy must include continuous monitoring of digital vulnerabilities alongside contingency planning for physical disruptions. By developing adaptive playbooks and ensuring secure collaboration among partners, organizations can better anticipate cascading threats, thereby ensuring operational continuity and fostering trust within the supply chain ecosystem.

Emerging technologies like blockchain and digital twins are accelerating this transformation. Blockchain enhances transparency and trust across multi-tier supplier relationships, while digital twins facilitate real-time modeling of potential disruptions. This shift enables companies to transition from reactive to predictive planning, establishing a connected ecosystem where visibility, security, and adaptability are integral rather than added later.

A Practical Roadmap for Resilience

Creating a resilient supply chain involves a practical multi-step roadmap aimed at progressively building capabilities. The first step focuses on establishing visibility and data integration, setting baseline Key Performance Indicators (KPIs) such as on-time delivery and inventory accuracy. The subsequent step introduces automation and advanced analytics to enhance forecasting and reduce cycle times.

The third phase embeds resilience measures, including supplier diversification and cyber-physical risk controls, with established metrics for risk reduction and recovery times. The final step advances toward predictive and adaptive capabilities through technologies like digital twins and blockchain, promoting continuous improvement and sustainability. This roadmap should evolve alongside market conditions, ensuring supply chains remain agile and secure.

Each step must link to measurable outcomes, such as reductions in cost-to-serve and improvements in service levels and resilience scores. This transparency allows organizations to assess the return on investment (ROI) effectively.

To secure executive buy-in for resilience investments, Kelian recommends reframing the conversation from cost to value. Resilience should be positioned as a strategic enabler, linking it to business continuity, customer trust, and competitive advantage. Instead of focusing solely on immediate ROI, organizations should emphasize measurable risk reduction, regulatory compliance, and the potential costs of inaction during disruptions.

Engaging executives early in the process is crucial. Aligning resilience initiatives with corporate objectives can present resilience as a driver of long-term growth and brand reputation. When leaders understand that resilience safeguards performance and bolsters shareholder confidence, investments in this area become a strategic necessity rather than a discretionary expense.

In conclusion, the future of supply chains lies in their ability to adapt, secure, and thrive amidst uncertainty. Developing a resilient, integrated approach to supply chain management is essential for organizations aiming to remain competitive in an increasingly complex global landscape.