Researchers from Beijing University of Technology and Beijing Building Construction Research Institute Co., Ltd. have unveiled a new method aimed at optimizing the design parameters for prestressed steel structures. This innovation addresses longstanding challenges in the construction of large-span buildings, particularly the complexities involved in balancing structural safety with material costs.

Traditional design practices often focus on single-factor optimization, resulting in lengthy design cycles and high computational expenses. The study, titled “Design Parameter Optimization Method for a Prestressed Steel Structure Driven by Multi-Factor Coupling,” seeks to overcome these limitations by employing a more integrated approach.

New Optimization Methodology

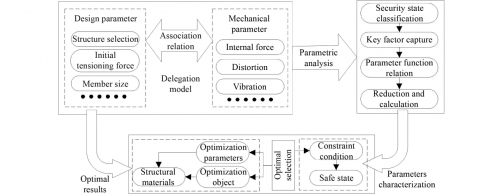

The research team, led by Guo-Liang SHI and Zhan-Sheng LIU, developed a numerical proxy model that connects design parameters (DPs) with mechanical parameters (MPs). This model facilitates a data association-parameter analysis-optimization selection system designed to enhance the correlation between these critical variables.

Utilizing a back propagation (BP) neural network, the researchers established how DPs influence MPs, which characterize the safety of the structure. Through safety grade analysis, the team identified key DPs that significantly affect the mechanical properties of the structure. They then created a mapping function that links these key DPs to their respective MPs.

To achieve optimal design parameters, the research employs a genetic algorithm (GA), targeting structural material costs while maintaining safety as a constraint. The effectiveness of this method was demonstrated through its application to an 80-meter span gymnasium, which was subsequently validated with a physical scale model.

Significant Findings and Impact

The results of the study indicate that the MPs derived from this new methodology align closely with experimental outcomes. Notably, the design cycle can be reduced by more than 90%, while material consumption can decrease by over 20% without compromising safety standards. Additionally, the research revealed that the cross-sectional dimensions of radial cables have a considerable effect on vertical displacement, with the initial tension and size of the upper and lower radial cables notably influencing their respective stress distributions.

The findings are detailed in the paper published in Frontiers in Structural and Civil Engineering in March 2024. The study’s authors, including De-Chun LU, Qing-Wen ZHANG, Majid DEZHKAM, and Ze-Qiang WANG, provide an innovative framework that could revolutionize the design processes of prestressed steel structures.

For further reading, the full text of the study is accessible at https://doi.org/10.1007/s11709-024-1084-0.