A team of researchers at EPFL has developed an innovative 3D printing technique that creates ultra-strong materials capable of withstanding pressures up to 20 times greater than those produced by traditional methods. This groundbreaking approach holds significant promise for applications in energy, biomedical devices, and advanced sensing technologies.

The new method diverges from conventional practices by using a water-based gel, known as hydrogel, to construct intricate scaffolds. Unlike previous techniques that relied on light to solidify a resin infused with metal precursors, researchers first create a 3D framework from the hydrogel. Subsequently, they infuse this scaffold with metal salts, which are chemically converted into metal-containing nanoparticles, allowing for exceptionally dense composite structures.

Daryl Yee, head of the Laboratory for the Chemistry of Materials and Manufacturing, emphasized the advantages of their process. “Our work not only enables the fabrication of high-quality metals and ceramics with an accessible, low-cost 3D printing process; it also highlights a new paradigm in additive manufacturing where material selection occurs after 3D printing, rather than before,” he stated.

Advantages of the New 3D Printing Technique

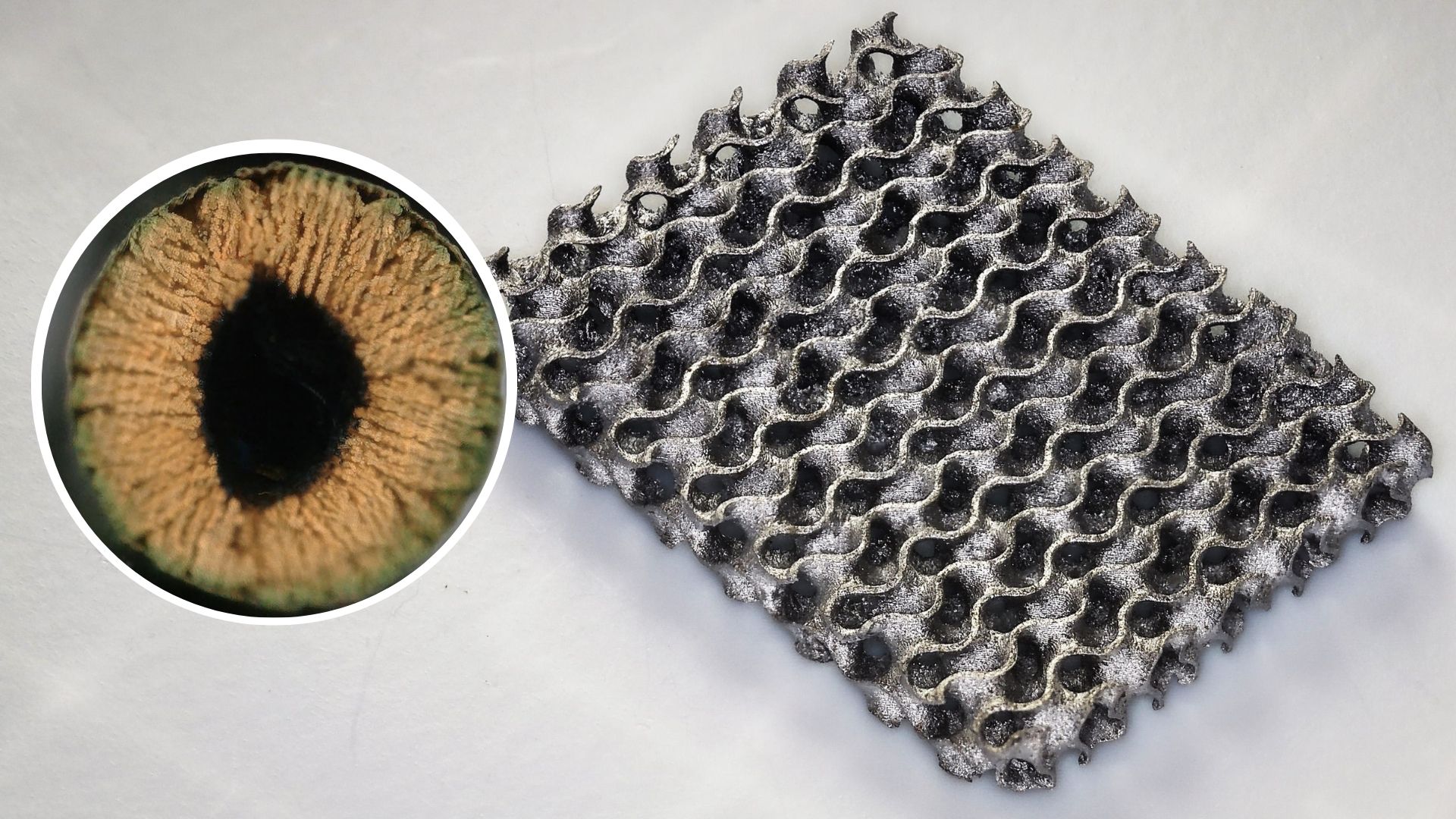

The research team, led by Yiming Ji, demonstrated that their materials exhibit remarkably low shrinkage, averaging only 20%, compared to the typical shrinkage rates of 60-90% seen in other methods. This capability allows for the production of complex geometric shapes, known as gyroids, using metals such as iron, silver, and copper.

To assess the strength of these structures, the researchers utilized a universal testing machine, applying increasing pressure to the gyroids. The results confirmed that the new materials could withstand much greater force, making them ideal candidates for advanced engineering applications that require a combination of strength, lightweight design, and intricate architecture.

Applications for this method are extensive. For instance, metal catalysts made with these materials could facilitate reactions that efficiently convert chemical energy into electricity. Additionally, the development of high-surface area metals with superior cooling properties could enhance energy technologies.

Publication and Future Implications

The findings were published in the journal Advanced Materials, highlighting a versatile method for fabricating dense architected ceramics and metals with low conversion linear shrinkages. The researchers noted that a post-fabrication infusion-coprecipitation process progressively increases metal loading within the 3D hydrogel structures. Following this, thermal treatment transforms the metal-rich hydrogels into robust ceramic or metal architectures.

“Our infusion-precipitation-based process enables the production of high-quality ceramics and metals, which is crucial for the creation of advanced architected materials and devices,” the researchers concluded. This advancement in 3D printing technology not only enhances the potential for creating sophisticated structures but also paves the way for innovations across multiple industries, from healthcare to energy solutions.