Researchers at the University of Portsmouth have developed an innovative method for recycling waste glass, turning it into building blocks for construction. This breakthrough could enhance the sustainability of building materials by utilizing powdered discarded glass as a stabilizing agent in compressed earth blocks (CEB). The study, which included contributions from scientists at three other universities, highlights a significant step toward reducing the environmental impact of glass waste.

Compressed earth blocks are typically made from soil, water, and cement, which are compressed under high pressure to create durable and sustainable bricks. This process generates far lower carbon emissions compared to traditional fired bricks. In standard CEB recipes, cement serves as a binder, improving the structural integrity of the blocks and protecting them from water damage. The challenge lies in finding alternative materials that can replicate the strength and durability of cement.

Dr. Muhammad Ali, a co-author of the research published in Discover Civil Engineering last month, explained the rigorous testing process the team undertook. “At each percentage level, we tested for water absorption and the blocks’ resistance to breaking under compression,” he said. “We also determined the maximum stress the block could withstand before deformation.”

Through their experiments, the researchers discovered that a mix comprising 10% lime and 10% recycled glass particles yielded the strongest blocks, with no signs of cracking under intense pressure. This finding suggests that CEB manufacturers could incorporate this blend to produce more sustainable building materials.

While the results are promising, the researchers acknowledge that further studies are needed to assess the long-term durability of these blocks under various conditions. The use of recycled glass in CEBs offers a viable solution for waste management, as traditional recycling processes for glass require significant energy and resources.

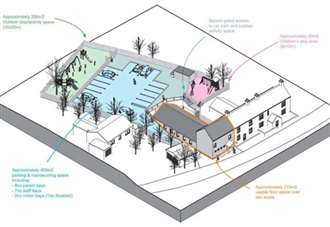

The potential applications for recycled glass-infused CEBs extend to low-rise residential and community buildings, such as schools and clinics, particularly in regions with low to moderate humidity. However, these blocks are not suitable for high-rise constructions typical in urban areas of developed countries. Given their reliance on locally sourced materials and labor, this approach could foster sustainable construction practices in many developing nations.

Globally, scientists are exploring various methods to prevent glass from ending up in landfills. Alternative applications for recycled glass include fire-resistant cladding, substituting sand in concrete for 3D printing, and creating insulating bricks combined with trash ash. Innovative efforts even include the development of a type of glass designed to break down in compost.

As the demand for sustainable building materials continues to grow, the success of this initiative will depend on the expansion of CEB usage and the integration of recycled glass into construction practices.