A team of chemists at Eindhoven University of Technology has developed an innovative method to recycle plastics using LED light, presenting a significant advancement in sustainable materials science. This breakthrough, led by Assistant Professor Fabian Eisenreich, enables a new class of high-performance plastics to be both created and broken down, promising a truly circular recycling process.

The research, published on August 15, 2025, in the Rising Stars edition of Advanced Materials, focuses on the concept of “design for recycling.” Eisenreich and his team from the Polymer Performance Materials research group aim to create new polymers that facilitate innovative recycling strategies, while also using organic materials and minimizing waste.

Breaking Down Barriers in Plastic Recycling

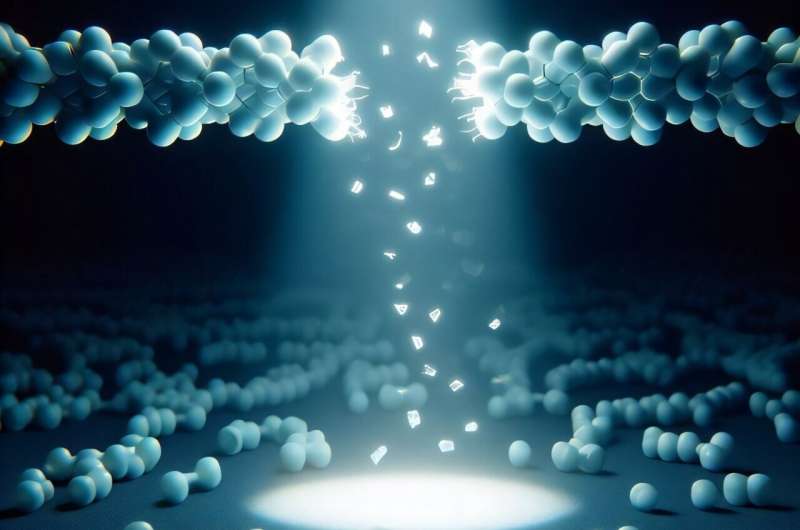

Traditionally, plastics lose quality during standard recycling processes, which involve heating and reshaping. This deterioration leads to an inevitable reliance on new plastic production. Eisenreich asserts that chemical closed-loop recycling offers a solution. “By selectively breaking down a polymer chain into its original building blocks, we can reuse these materials to create the same polymer with identical properties,” he stated.

Eisenreich’s focus is on photochemical recycling, an area powered by LED light. “While creating polymers with light is straightforward, recycling them in the same manner is significantly more complex,” he explained. The challenge lies in using light to selectively break stable chemical bonds within the polymer, allowing the original building blocks to be recovered for reuse.

Recently, Eisenreich and Ph.D. candidate Ahsen Sare Yalin achieved a milestone by successfully demonstrating this selective breakdown in their lab. This development is seen as a groundbreaking step towards reshaping plastic waste management.

Future Applications and Innovations

Currently, the designer polymer is considered a niche material, primarily aimed at specialized applications such as recyclable adhesives. Eisenreich acknowledges that further research is needed to expand its practical applications. “We envision a future where closed-loop recycling technology is not only confined to specialized uses but also applicable to everyday products,” he remarked.

Additionally, Eisenreich is exploring the potential of 3D printing using recyclable polymers activated by light. This process enables the transformation of liquid materials into solid forms upon exposure to light, facilitating the creation of complex three-dimensional objects. His ultimate goal is to achieve photochemical recycling of traditional plastics using only sunlight, eliminating the need for other energy sources.

Eisenreich’s pioneering work is illuminating not just the future of plastic recycling but also offering a new perspective in the field of sustainable chemistry. “This is not just a new material. It’s a new way forward,” he concluded.

For further insights, the full research can be found in the publication by Yalin et al, titled “A Light-Driven Closed-Loop Chemical Recycling System for Polypinacols,” available in Advanced Materials, DOI: 10.1002/adma.202506733.