In 2013, Motorola embarked on an ambitious project to produce its Moto X smartphone in the United States, aiming to appeal to consumers who prioritized domestic manufacturing. This initiative, however, was short-lived, lasting just one year before the company closed its Texas factory. Dennis Woodside, former CEO of Motorola and current CEO of Freshworks, reflects on this experience as companies today consider similar endeavors amidst changing economic pressures.

The Moto X was designed to compete with leading smartphones from Apple and Samsung, marketed under the slogan “Made in the USA.” Woodside noted that there was a segment of consumers who were more inclined to purchase products manufactured domestically. Unfortunately, despite the appeal, sales failed to meet expectations, with only **500,000 units sold** in the third quarter of 2013, according to analysis from Strategy Analytics. By May 2014, Motorola had ceased domestic assembly of the Moto X due to higher costs and a fragmented supply chain.

The challenges faced by Motorola in the early 2010s remain relevant as economic pressures mount for tech companies to consider manufacturing within the United States. With President Donald Trump advocating for domestic production and the impending tariffs on imports from China set to take effect on **August 12, 2024**, the landscape for smartphone assembly is shifting once again. Notably, India has emerged as the top exporter of smartphones to the U.S., poised to encounter a **25% tariff** on its products if new rates are implemented.

Woodside emphasizes that companies must not underestimate the difficulty in sourcing skilled labor for domestic manufacturing. “You have to have a very strong value proposition to the employee,” he stated. He advises businesses to be strategic regarding automation and to ensure that their operations remain price-competitive.

In its attempt to customize the Moto X, Motorola provided consumers with the option to personalize aesthetic features such as button colors and back panels. This customization required the assembly process to be closer to the consumer base. However, despite these innovations, the components of the Moto X were primarily sourced from suppliers in Asia, underscoring the challenges of establishing a fully domestic supply chain.

The factory in Fort Worth, Texas, was capable of assembling about **100,000 phones per week**, but ultimately, the lack of consumer demand and the high costs associated with domestic assembly made the initiative unsustainable. Woodside noted that the task involved intricate assembly of numerous small parts, which he compared to working with “super tiny Lego sets.”

A significant hurdle for Motorola was the recruitment and retention of skilled workers. Many available employees opted for jobs in retail or food service, making it difficult to fill factory positions. The specific nature of phone assembly work also posed challenges, as most individuals were not accustomed to such tasks.

The U.S. manufacturing sector has faced its own challenges recently, with the Bureau of Labor Statistics reporting an estimated **11,000 manufacturing jobs lost** between June and July 2024. This situation highlights a broader trend of skill shortages that complicate the task of bringing tech manufacturing back to American soil. A survey by the Cato Institute indicated that most Americans do not view factory work as preferable to their current employment.

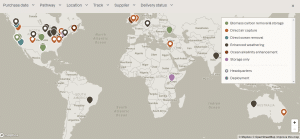

In contrast, China continues to thrive in the manufacturing sector, employing approximately **123 million people** in 2023. The country has established an extensive labor pool ideal for smartphone assembly, particularly within facilities such as Foxconn’s Zhengzhou plant, where assembly lines operated at remarkable speeds.

Apple has also begun diversifying its manufacturing locations, shifting some production to India and Vietnam to reduce reliance on China. This strategic move not only responds to economic pressures but also reflects the evolving landscape of global manufacturing.

As the industry faces increasing automation and the integration of artificial intelligence, new manufacturing jobs will require updated skills, including coding and data analytics. Woodside warns that companies considering domestic production must thoroughly assess whether they can cultivate a workforce with the necessary skills for modern manufacturing.

“Understanding the nature of the product you’re making, and thinking about… ‘Are we going to have to completely train the workforce to understand this specific product?’ That’s something we didn’t quite anticipate,” he concluded.

The lessons learned from Motorola’s foray into U.S. smartphone manufacturing serve as a cautionary tale for current and future endeavors. With the economic landscape shifting, companies must carefully evaluate the complexities of domestic assembly, workforce availability, and global supply chain dynamics.