Researchers at Beihang University have developed an innovative approach to enhance aircraft safety by addressing a critical issue encountered during aircraft assembly. Their study, titled “Detection and Removal of Excess Materials in Aircraft Wings Using Continuum Robot End-Effectors,” focuses on the removal of excess materials, such as nuts, rivets, and aluminum shavings, which can compromise the functionality of essential aircraft components. The presence of these materials poses significant risks, potentially leading to serious flight accidents.

Challenges of Manual Removal in Confined Spaces

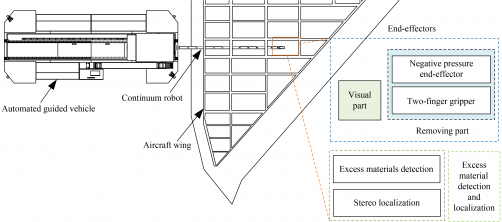

Currently, the majority of inspection and removal tasks are performed manually. However, the confined spaces within aircraft wings make this process challenging. Traditional robotic systems often struggle to navigate these narrow and complex environments, resulting in low efficiency in removing excess materials. As a solution, the research team has designed a continuum robot specifically equipped for this task, incorporating advanced technologies aimed at improving operational effectiveness.

The study begins with an analysis of the size and weight characteristics of excess materials found in aircraft wings. Based on these findings, the researchers engineered a novel negative pressure end-effector along with a two-finger gripper. The negative pressure end-effector is tailored for the removal of smaller items such as nuts and small rivets, while the two-finger gripper is designed to handle larger volumes of aluminum shavings.

Advanced Detection Techniques and High Accuracy

To overcome the challenges posed by poor lighting conditions inside the aircraft wing compartments, the team integrated supplementary lighting devices to enhance visibility. For the detection and classification of excess materials, they employed the You Only Look Once (YOLO) v5 algorithm, which is known for its efficiency in real-time object detection. The researchers created two distinct training datasets tailored for different types of wings, ensuring the system’s accuracy.

Given the limited texture features within the aircraft wings, the team utilized an image-matching method based on the detection results from YOLO v5. This approach effectively mitigated performance instability issues often associated with traditional feature point matching techniques, such as Oriented Fast and Rotated BRIEF.

Experimental results reveal that the detection accuracy for each type of excess material exceeds 90%, while the visual localization error remains below 2 mm for four types of detected objects. The two end-effectors are shown to successfully perform the removal tasks, demonstrating their effectiveness in enhancing safety during aircraft assembly.

The findings from this research provide a promising advancement in aircraft safety and operational efficiency. The full text of the paper, which outlines these significant developments, is available at https://doi.org/10.1007/s11465-024-0806-2.

This innovative research underscores the potential of robotics in addressing critical issues within the aerospace industry, paving the way for safer and more reliable aircraft operations.