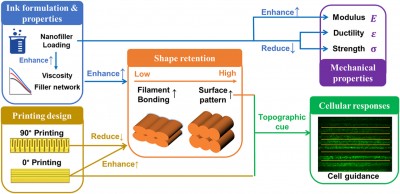

A recent study has unveiled significant advancements in the field of 3D printing, particularly concerning bioactive implants designed for bone repair. Researchers have demonstrated that the combination of ink composition and printing design plays a crucial role in determining the structure, strength, and bioactivity of these implants. By fine-tuning these elements, they have developed implants that not only enhance bone cell growth but also provide greater stability.

The research emphasizes the importance of materials and design in creating effective bone implants. Through a series of experiments, scientists found that variations in ink composition can lead to substantial differences in the performance of the implants. For instance, specific blends of materials were identified that foster an environment conducive to bone cell proliferation while maintaining the mechanical integrity necessary for long-term use.

Advancements in Personalized Treatment

This innovative approach opens new avenues for personalized treatment strategies in bone repair. Traditional implants often follow a one-size-fits-all model, which may not address the unique needs of individual patients. The findings from this study suggest that customized implants could significantly improve patient outcomes by better aligning with the biological demands of their specific bone conditions.

The researchers utilized advanced 3D printing techniques to create implants tailored to individual patient profiles. This customization process involves analyzing patient-specific data, which allows for the design of implants that meet precise biological criteria. Such developments could lead to more effective treatments for conditions such as fractures, bone defects, and other orthopedic issues.

The implications of these findings extend beyond the laboratory. Improved bioactive implants could lead to reduced recovery times and enhanced integration with the body’s natural tissues. As a result, patients may experience faster healing and improved functionality after procedures involving bone repair.

Future Directions and Potential Impact

Looking ahead, the research team plans to explore further enhancements in material science and printing technologies. Ongoing studies will likely focus on refining the ink compositions and developing even more sophisticated designs that optimize bioactivity and mechanical performance.

The potential for commercialization of these advanced 3D-printed implants is significant. With the orthopedic implant market projected to grow substantially in the coming years, innovations such as these could position companies at the forefront of a transformative shift in how bone repairs are approached.

In conclusion, the interplay of materials and design in the 3D printing of bioactive implants marks a promising advancement in the medical field. As researchers continue to refine these techniques, the prospect of personalized, effective bone repair solutions becomes increasingly tangible. This study not only highlights the importance of innovation in medical technology but also underscores the potential for improved patient care through tailored treatment options.