A groundbreaking facility designed by inventor Naturejab has successfully converted scrap plastic into usable fuel through a solar-powered pyrolysis process. This innovative reactor, touted as the world’s most complex hand-made pyrolysis machine, showcases a unique approach to addressing plastic waste and energy needs.

The pyrolysis process involves applying heat to organic materials in an inert environment, leading to the breakdown of their chemical structures. In this case, discarded plastic is decomposed into its original components: natural gas and petroleum. Operating entirely on solar energy, the facility features a 100 kWh Komodo commercial power tank and approximately twenty solar panels, generating between eight to nine kilowatts of power.

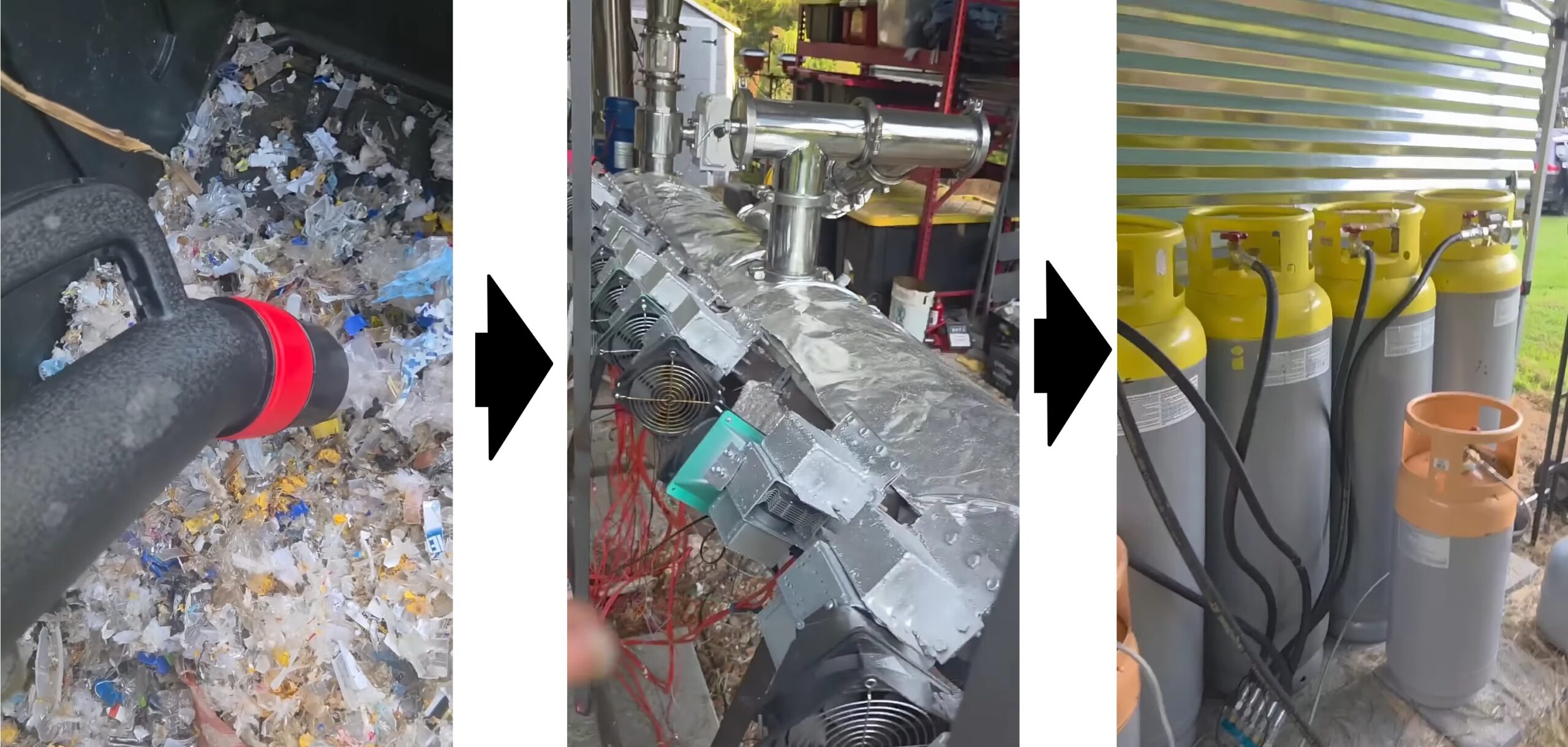

The operation begins by loading scrap plastic into the machine through a vacuum pump connected to a flexible tube. Once the plastic is in the main vacuum chamber, the system employs eight active magnetrons, similar to those used in standard microwave ovens, to facilitate the breakdown of the plastic. The absence of air in the chamber prevents combustion; instead, the material melts, transforming back into petroleum and natural gas vapor.

As the process continues, the resulting vapor passes through a dephlegmator, which cools it down into crude oil and natural gas. These products are then stored separately for future use and processing, allowing for a sustainable solution to plastic waste.

The facility represents a significant step towards renewable energy and waste management. By converting plastic waste into fuel, it not only addresses environmental concerns but also contributes to energy creation in a sustainable manner. For those interested in advancements in pyrolysis technology, related topics such as Methane Pyrolysis may offer further insight into producing green hydrogen without carbon emissions.

This innovative approach highlights the potential of renewable energy solutions to tackle pressing environmental issues while paving the way for future advancements in waste management technologies.